Why these sensors are worth paying attention to

LMI Technologies has introduced a new generation of laser sensors for 3D profiling - the Gocator 6300 series. The sensors deliver a combination of high speed, extreme accuracy and advanced optics for demanding measurement and inspection applications.

What does the Gocator 6300 offer and what applications will you use it best in? Let's take a look

Key features:

The Gocator 6300 series is built on advanced profiling technology that delivers the following:

- Over 6,500 points per profile for 2D/3D measurement and inspection

- X-axis data interval below 2.1 microns (at 13.4 mm frame width)

- Z-axis repeatability up to 0.15 microns

- Scan rate over 1,800 Hz per full frame

- Frame width up to 31 mm at high resolution (X interval < 4.3 microns)

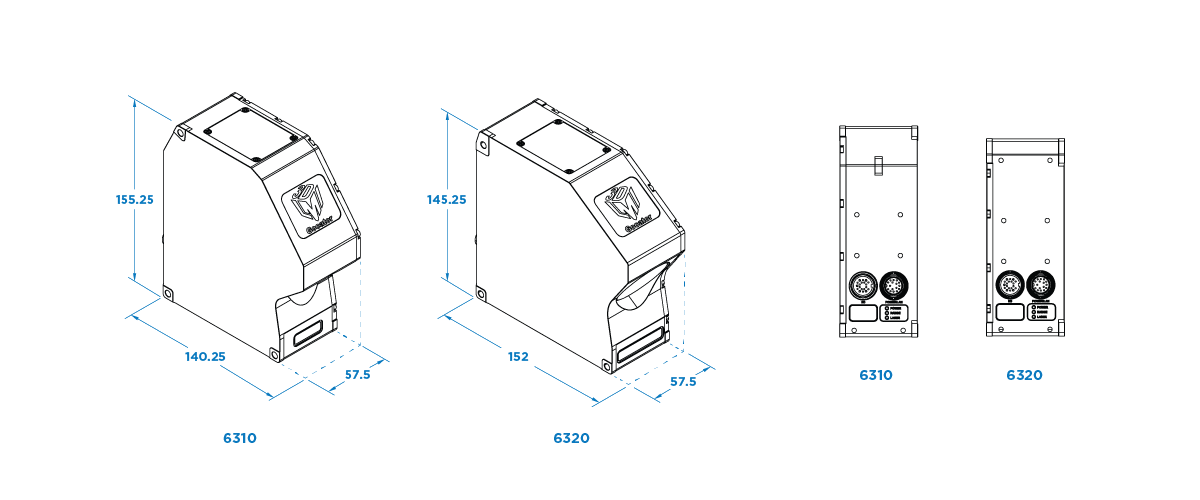

The 6310 and 6320 use a telecentric laser line generation and a special high numerical aperture lens. This allows them to achieve excellent edge detection and accurate measurement even on curved, tilted or reflective surfaces.

In addition, for demanding tasks, the sensors can be easily connected in multi-sensor systems without complex calibration.

Typical Gocator 6300 applications

The series is designed for demanding industrial applications where accuracy, speed and reliability are key. It provides solutions for a wide range of production areas:

Electronics and semiconductors

Quality control of solder joints on PCB boards. When manufacturing printed circuit boards (PCBs), it is necessary to check that all solder joints are made correctly, without cold joints, bridging or missing connections. Thanks to its high resolution and speed, the Gocator 6310 can identify even microscopic defects on solder points, which is essential for the reliability of final electronic devices.

Automotive

Inspection of weld seams on body parts. In automotive manufacturing, weld quality is critical to vehicle safety. The Gocator 6320's wide-range, advanced edge detection allows you to measure the shape, height and consistency of weld seams on large and curved body surfaces - even where conventional sensors fail due to reflections or material curvature.

Precision Engineering and Metrology

Scanning and measuring optical components. In the manufacture of precision optical components, there is a need to check the flatness and shape variations of surfaces at the micron level. With its telecentric optics and high numerical aperture, the Gocator 6310 can scan even the subtle curvature of glass or metal surfaces without being affected by reflection distortion.

Packaging and Consumer Goods

Inspection of the shape and integrity of packaging. When producing packaging, it is necessary to ensure not only the correct dimensions, but also the integrity and aesthetic quality of the surface. The Gocator 6300 Series can inspect the shape of plastic or metal packaging in real time and reliably detect dents, scratches or manufacturing defects that could affect the appearance of the product.

What makes the Gocator 6300 truly special?

In addition to its superior performance, the sensor brings several major innovations:

- Telecentric laser line generation: ensures a consistent beam size across the entire measuring range, significantly increasing measurement accuracy.

- Custom designed optics with high numerical aperture: Maximum light gathering means better results even on challenging, shiny or dark surfaces.

- Scalability: sensors can be easily combined into multi-sensor solutions without complex calibrations, allowing you to measure larger objects or more complex shapes.

All this is complemented by the intuitive Gocator web interface, which makes it easy to set up measurement tasks without programming.

From selection to integration: we're here for you

AMV Technology is a machine vision partner of LMI Technologies. Our colleagues will help you to select the right model and ensure the correct integration of the sensor into your production process.

Contact us - we will be happy to discuss your specific requirements and show you how the new Gocator 6300 series can be deployed in your application.

Team AMV