LMI Technologies Case Study: How FAW-Volkswagen Solved Pin Height Inspection Directly on the Production Line

In automated manufacturing, details matter. And sometimes it’s not micro-cracks or surface defects, but worn steel pins that hold the car body during the painting process.

One of the case studies by our partner LMI Technologies shows how FAW-Volkswagen successfully combined precise 3D measurement with automation. By intelligently deploying Gocator 2540 sensors, they solved a problem that had previously caused inefficiencies, high costs, and potential operational risks.

Why Monitoring Pin Height Matters

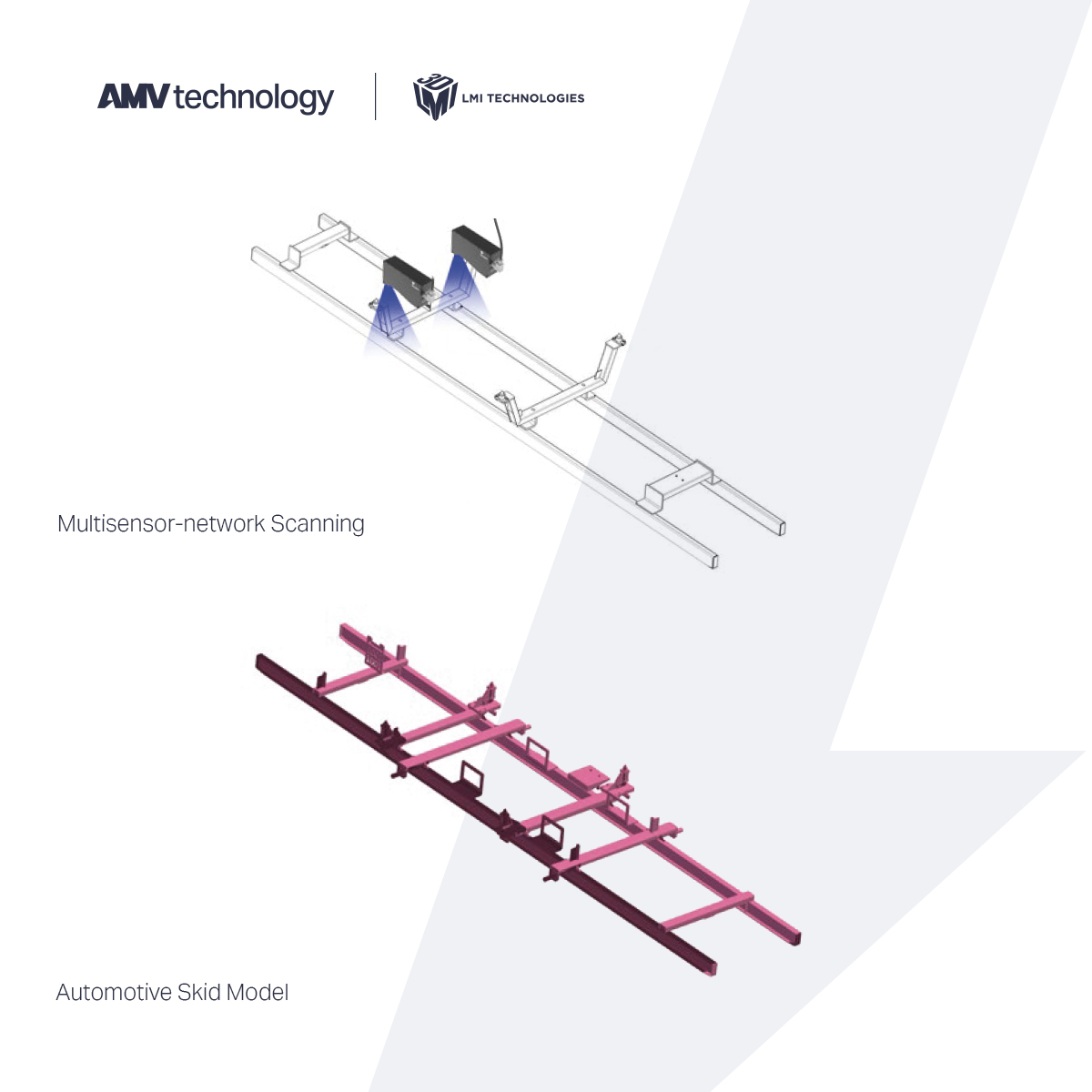

So-called skids—metal structures that support the car body during the painting process are exposed to harsh conditions. High temperatures, chemicals, and mechanical wear can gradually alter the height of the supporting pins.

This is not a minor issue. If the pins wear down below the required height, the car body can tilt or even tip over during handling. In a production environment where every second and every micron counts, this represents a critical risk.

To address this, FAW-Volkswagen decided to replace manual inspections with a fully automated system capable of measuring and evaluating pin height directly on the production line without interrupting operations.

The Solution: 3D Measurement with Gocator Sensors

The implementation was led by the digital division of the Foshan plant. The goal was to introduce a fully automated inspection solution that would be fast, accurate, reliable, and easy to integrate into the existing production line.

The selected solution uses a pair of Gocator 2540 3D laser sensors in combination with a Master 810 controller.This setup enables simultaneous scanning of both sides of the skid and its connection points at high resolution and speeds of up to 20 kHz. All data processing is performed directly on the sensor—no external software or PC required.

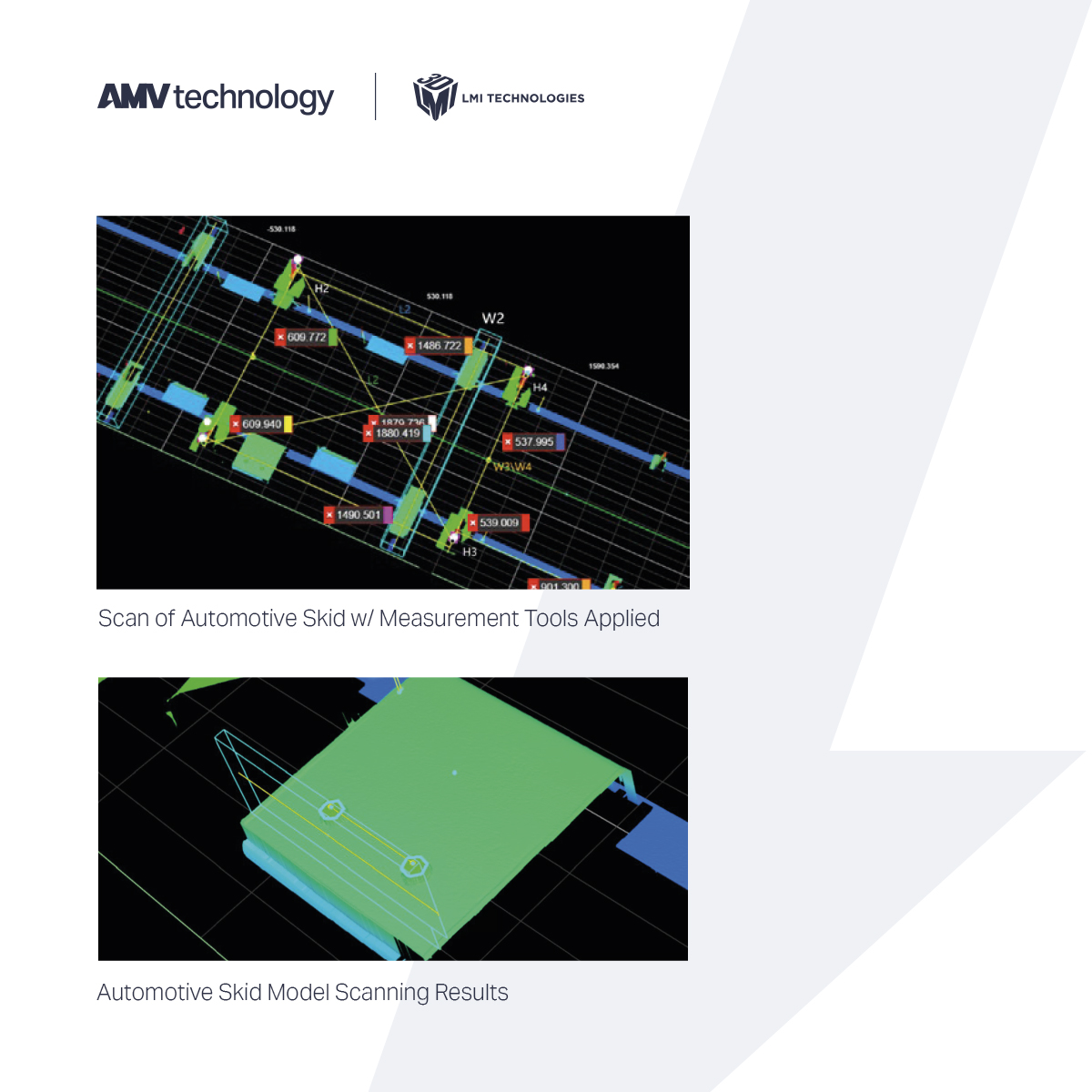

After acquiring the 3D data, the system automatically:

– performs calibration,

– establishes the coordinate system,

– identifies key structural features,

– and executes a complete dimensional evaluation.

All of this happens in real time, without any production downtime. The system is also connected to a database, enabling data archiving and supporting predictive maintenance strategies.

The Result: Lower Costs, Higher Accuracy, 100% Inspection

The benefits were immediate. Manual handling of skids was eliminated, the inspection process became faster, and accuracy improved thanks to micron-level measurement. Thanks to straightforward integration with the production PLC, deployment was quick and complication-free.

As Tao Chen, Maintenance Technician at FAW-Volkswagen Foshan, summarizes:

“The easy deployment and advanced 3D profiling capabilities of Gocator have fundamentally transformed our inspection process. The system’s accuracy and seamless integration have significantly improved efficiency, reduced costs, and enabled 100% inspection.”

Technology We Use in Practice as Well

Gocator technology from LMI Technologies is built around real industrial needs. It delivers high accuracy, repeatability, easy integration, and a robust web-based interface—all without the need for additional software tools.

At AMV Technology, we know this technology well. We train with it, test it, and deploy it in real-world applications. Whether it’s height measurement, volume measurement, deviation detection, or other inspection tasks, Gocator is a strong choice wherever speed, precision, and reliability are essential.

Interested in This Case Study?

Get in touch with us, we’ll be happy to discuss whether a similar solution could work in your production environment.

Source: Case Study LMI Technologies / FAW-Volkswagen Automotive Skid Inspection

www.lmi3d.com

Team AMV