How Sentinel Vision Advanced the Inspection of Plastic Molded Parts Using 3D Machine Vision

Injection-molded plastic parts are virtually everywhere today in automotive, electronics, healthcare, and industrial applications. What all these industries have in common is a strong focus on quality and minimal tolerance for defects. However, the most common defects are often the most difficult to detect during production.

One of the case studies published by our partner Zebra Technologies describes a solution developed in collaboration with Sentinel Vision and Clearview.The result is an inspection system that enables 100% inspection of plastic parts in real time, without the need to slow down or stop production.

Manufacturing Challenge: Defects That Are Hard to See at First Glance

Typical defects in injection-molded plastic parts include:

- flash along mold parting lines,

- jetting — wavy surface marks caused by high-velocity material flow,

- short shots (incompletely filled parts),

- surface delamination,

- sink marks caused by material shrinkage.

Due to low surface contrast, translucent materials, and complex part geometries, traditional inspection methods — long reliant on manual visual checks or simple mechanical sensors — often failed to deliver reliable results. Sentinel Vision therefore sought a solution that would be accurate, scalable, and suitable for a wide range of production environments.

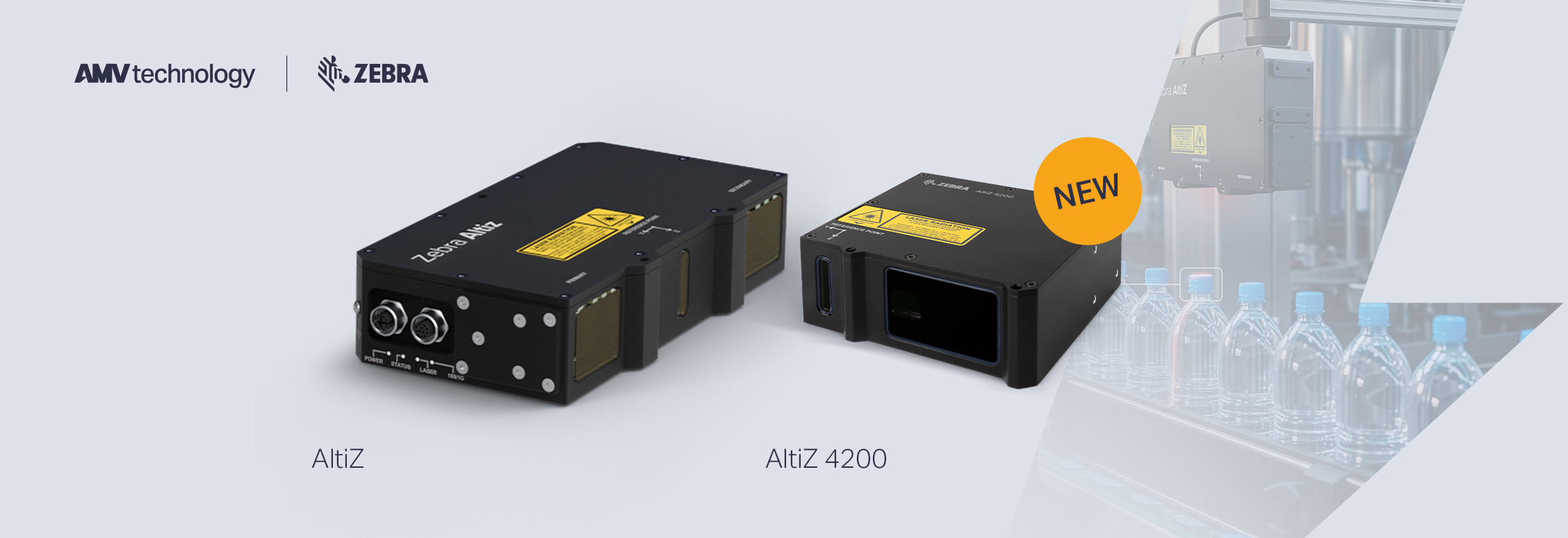

The Solution: 3D LaserScan with Zebra AltiZ Sensors

In collaboration with Clearview, a Zebra Technologies industrial automation partner, Zebra AltiZ 3D profile sensors were selected. These sensors use a dual-camera, single-laser configuration, enabling the inspection of complex plastic part geometries while minimizing optical occlusions in deep cavities or along edges.

The sensors were integrated into Sentinel Vision’s proprietary 3D LaserScan solution — a standalone inspection unit designed for direct integration on injection molding machines. The system combines precise hardware with advanced VisionCore software, which merges 2D and 3D image analysis.

Operators interact with the system via a touchscreen interface, allowing them to:

- set inspection parameters,

- adjust tolerances,

- review inspection results — all without the need for programming.

What the System Can Do Directly on the Production Line

Within seconds after a part is ejected from the mold, the system can:

- perform dimensional inspections,

- compare parts against CAD models,

- detect visual and structural defects that conventional 2D cameras would often miss.

Deployment takes less than one hour, making the solution suitable for both high-volume and low-volume production environments.

Benefits in Practice

Manufacturers who have deployed the system have achieved:

- 100% inspection coverage without impacting line throughput,

- significant reductions in scrap and rework,

- fast return on investment (typically within six months),

- actionable data for optimizing the injection molding process.

The solution is currently deployed in European manufacturing facilities and is being prepared for global rollout across multiple industries — from medical components to heavy-duty industrial parts.

Want to Learn More?

We recently published a separate article focusing on AltiZ 3D profile sensors and the newer AltiZ 4200 series from Zebra Technologies. If you are interested in the technical background and key differences between these solutions, you can find more details there.

A Reference We Also Work With

This case study demonstrates how Zebra Technologies’ Machine Vision portfolio performs in real-world manufacturing environments. At AMV Technology, we work with these technologies hands-on — testing them, integrating them, and adapting them to specific customer applications.

If you are addressing quality inspection challenges for plastic parts or other demanding inspection tasks, feel free to contact us. We would be happy to discuss whether a similar approach could work in your production.

Source: Zebra Success Story / Sentinel Vision / Clearview

Team AMV