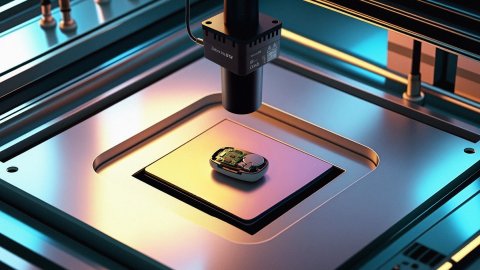

High-Performance and Compact Smart Camera for Industrial Applications

Automated quality inspection today means more than just capturing an image. Manufacturers must address speed, accuracy, limited installation space, and the need for real-time response — while keeping the overall system architecture as simple as possible.

These requirements are precisely what Iris GTX from our partner Zebra Technologies is designed to meet. It is a high-performance smart camera that combines high-resolution imaging, embedded processing power, and deep learning support within a single compact device.

Image Processing Directly in the Camera

Iris GTX operates as an edge IoT device. Image acquisition and analysis take place directly within the camera housing, and the results are transmitted to higher-level control systems or automation components via digital I/O and industrial interfaces.

In practical terms, this means:

-

No separate industrial PC is required for typical applications

-

Fast response directly on the production line

-

Simplified system architecture

The camera is built around the Intel® Atom® x6211E dual-core processor with burst frequencies up to 3.0 GHz, complemented by 4 GB RAM and 32 GB of internal storage. This enables it to handle both traditional machine vision tasks and deep learning inference directly on the device.

High Resolution and Frame Rate Performance

Iris GTX is available in multiple variants featuring CMOS sensors with resolutions ranging from 2 to 16 megapixels.

Depending on the specific model, it offers:

-

Up to 70 frames per second at 1920 × 1200 resolution

-

Up to 21.6 frames per second at 4000 × 4000 resolution

This makes it suitable for high-speed inline inspection as well as applications where fine detail and high image data density are critical.

Iris GTX Model Overview

Iris GTX is not a single camera but a scalable platform. Below is a summary of the available model

| Parameter | GTX 2000 | GTX 2000C | GTX 5000 | GTX 5000C | GTX 8000 | GTX 8000C | GTX 12000 | GTX 12000C | GTX 16000 | GTX 16000C |

|---|---|---|---|---|---|---|---|---|---|---|

| Sensor Model | XGS 2000 | XGS 2000 | XGS 5000 | XGS 5000 | XGS 8000 | XGS 8000 | XGS 12000 | XGS 12000 | XGS 16000 | XGS 16000 |

| Sensor Type | CMOS | CMOS | CMOS | CMOS | CMOS | CMOS | CMOS | CMOS | CMOS | CMOS |

| Sensor Size | 1/1.25" | 1/1.25" | 2/3" | 2/3" | 1/1.1" | 1/1.1" | 1" | 1" | 1.1" | 1.1" |

| Version | Mono | Color | Mono | Color | Mono | Color | Mono | Color | Mono | Color |

| Resolution | 1920 × 1200 | 1920 × 1200 | 2592 × 2048 | 2592 × 2048 | 4096 × 2160 | 4096 × 2160 | 4096 × 3072 | 4096 × 3072 | 4000 × 4000 | 4000 × 4000 |

| Maximum Frame Rate | up to 70 fps | up to 17 fps | up to 41.7 fps | up to 10 fps | up to 39.6 fps | up to 10 fps | up to 28 fps | up to 7 fps | up to 21.6 fps | up to 5 fps |

Machine Vision and Deep Learning in One System

Iris GTX supports both traditional machine vision tools and deep learning inference directly on the device.

Typical applications include:

-

Dimensional measurement and position verification

-

Surface defect inspection

-

Code reading and marking verification

-

Sorting and product classification

Applications can be developed using Aurora Design Assistant, a flowchart-based development environment that enables system configuration without traditional programming. For advanced customization, Aurora Imaging Library is available as a comprehensive software development kit (SDK).

Compact and Rugged Design

The IP67-rated housing allows deployment in dusty and humid industrial environments. Compact dimensions of approximately 75 × 57 × 75 mm facilitate integration even in space-constrained installations.

The camera provides:

-

Gigabit Ethernet

-

USB and VGA output

-

Digital I/O

-

Industrial-grade connectors

Integrated lens focusing control and illumination intensity management directly from the software simplify both installation and maintenance.

Our Approach at AMV Technology

At AMV Technology, we specialize in integrating machine vision systems into industrial applications. As a partner of Zebra Technologies, we not only supply Iris GTX but also test and deploy it in real production environments.

Each project is evaluated based on the specific application requirements — accuracy, process speed, mechanical constraints, and environmental conditions. Based on this analysis, we recommend the appropriate camera model and design its integration into the overall system architecture.

If you are planning a new application or upgrading an existing quality inspection system and are considering a smart camera as a standalone edge solution, we will be glad to assess whether Iris GTX is the right fit for your operation.

AMV Team